The holographic design is embossed on metalised PET in width of upto 160 mm for the manufacture of security labels and strips.

Manufacturing stages of Holograms:

Holograms are embossed using the masters made using laser beams from the artwork. Different methods are used for making the master depending on the security features to be incorporated in the design. The colors in the holograms changes with the angle of viewing by the user

Can have 2 or 3 layers in the hologram having virtual depth between the layers. These masters have their limitations for incorporation of high security features which is the need of the times. Some features that can be provided in the layers are flip flop ( switching effects), floating effects, microtext, CLR,. etc.

Electron beams are used for making the masters. As electron beam have very high dpi more security features can be provided. Such holograms are used for extremely high volume, high security products

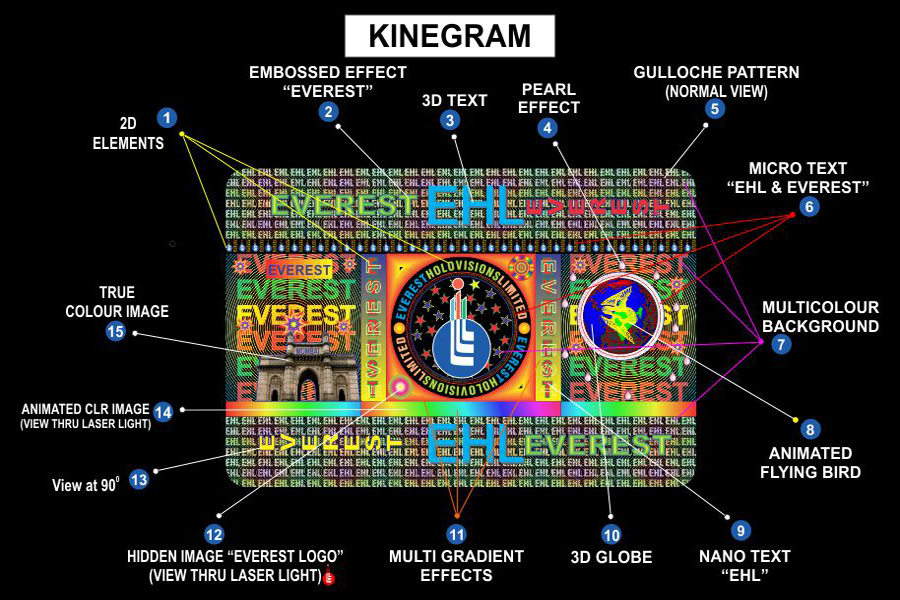

Holograms supplied may have both Overt and Covert security features.

Overt features are directly visible to the end user for ease identification of genuine products. The overt features are complex, attractive and are difficult to replicate. Some of the overt features are Guilloche patterns. Embossed effect, Gradient and kinetic effects, etc.

Security features which are not visible to the naked eye and requiring some kind of devices are the covert features. Nano text, laser readable image, raster effects etc.. are some of the covert features. As the features are known only to the manufacturer, it assists the personnel to on field checks for authenticity of the product.

Easily scan able variable data provided through Thermal printed holograms are used by manufacturers for inventory control, tracking the products through the distribution channel and preventing duplication The printing are very economical, however the printed data can be erased using some solvents

Holograms are supplied with tamper evidence properties which provide clear evidence when anybody attempts to remove the label. When hologram is tried to be peeled the design gats mutilated and the label cannot be again affixed to the product or packaging. Tamper evidence properties are an added level of security. They are being used by many industries where sealed packages have to reach the consumer as a proof of authenticity.

The tamper evidence properties are supplied as:-